Description

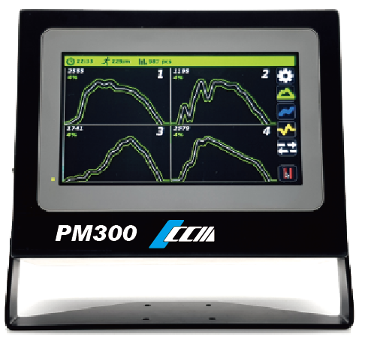

New Product Post Test Process Monitoring PM300

Features

- Automatic pressure curve learning

- Forging pressure trend detection

- Automatic start mode, the whole process of automatic monitoring of the production process

- 7-inch color touch screen

- Graphical interface is easy to operate

- Automatically record the production status of the day

- Automatically record 1000 production shutdowns

- Supports up to 6-Channel pressure bar sensor

< Slide left and right to view product specifications >

Specifications

Filterable items

Optional

Video

instruction

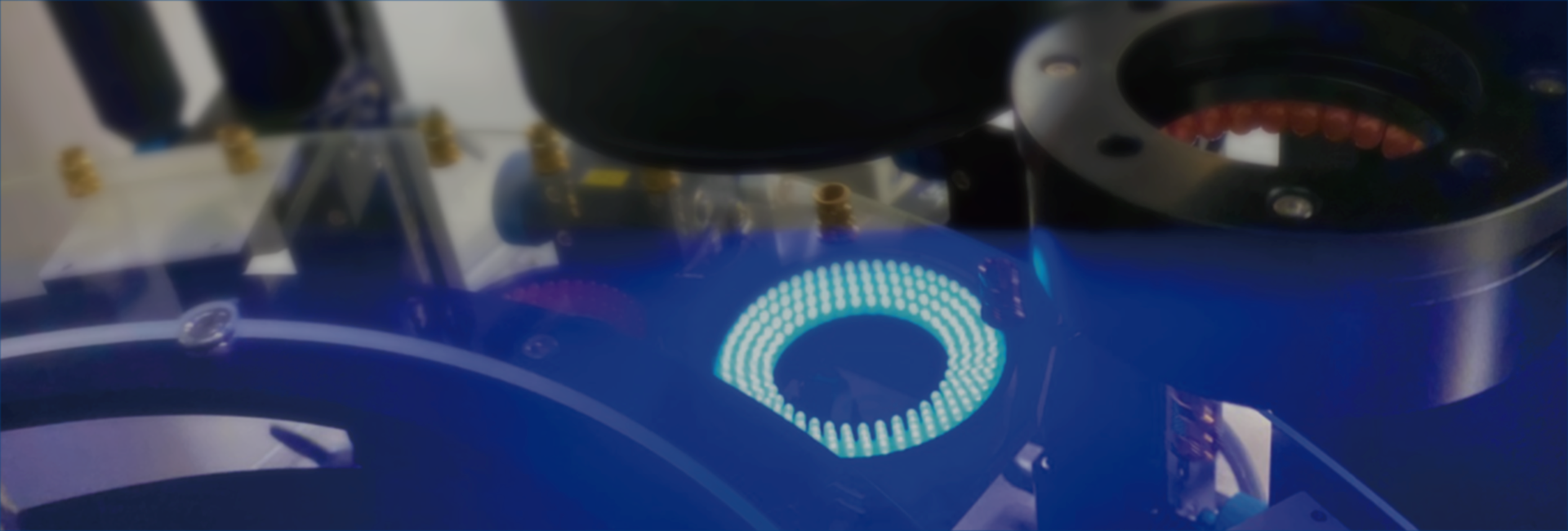

- For M3~M8 Screws and bolts, under head length less than 80mm

- Available for 2~5 cameras

- Can install rotating mechanism to inspect recess depth or broken pin

- Optional: wheel crack checking system (LS-1501)for head crack inspection

- Optional: bottom sorting system(LS-1503)for inspecting cutter presence.

- Optional: Bending checking module

- Optional: Eddy current system for material mix-up or with/without heat-treatment

- Pitch Distance

- Feature No.

- bevel thread

- Screw Length

- Feature Similarity

- Cone Point

- Zinc:Yes or No(Head Top View)

- Feature Length

- Pinhole Alignment

- Head Crack

- AF/AC

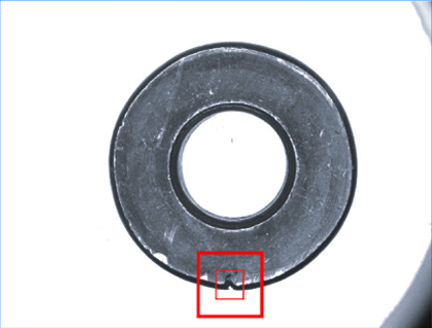

- Head Mark

- Mixed Material

- Inner Roundness

- Inner Concentricity

- Broken pin

- Inner Excess Material

- Shorten AF

- Deformed thread

- Feature-Center Distance

- Roundness

※One-way bearing: One-way bearing is used for feeding to prevent the wire from backing up.

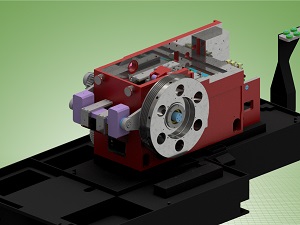

※五模及六模長尺寸特殊零件成型機CPS & CPD SERIES 5 &6 STATION BOLT PARTS FORMER

左右滑動查看表格

| 機型 | CPD-10B | CPS-10B | CPS-13B | CPS-17B | CPS-19B | CPS-24B | CPS-30B | CPS-36B | CPD-13B6SL |

| 規(guī)格 | |||||||||

| 模數 | 5 | 6 | 5 6 | 5 6 | 5 6 | 5 6 | 5 6 | 5 6 | 6 |

| 最大切斷直徑(mm) | 12 | 12 | 15 | 17 | 19 | 23 | 30 | 34 | 16 |

| 最大切斷長度(mm) | 120 | 100 | 110 | 140 | 135 | 200 | 250 | 280 | 180 |

| 後托頂出長度(mm) | 110 | 80 | 85 | 120 | 145 | 175 | 220 | 260 | 170 |

| 前托頂出長度(mm) | 25 | 25 | 25 | 30 | 35 | 45 | 45 | 50 | 30 |

| 夾子翻轉長度(mm) | 25 | 25 | 40 | 40 | 60 | 70 | 100 | 120 | 40 |

| 切模 (DXL mm) | 40x60 | 40x60 | 50x80 | 50x80 | 60x100 | 75x100 | 95x120 | 110x155 | 50x80 |

| 母模(DXL mm) | 50x130 | 50x130 | 70x135 | 80x150 | 95x175 | 108x200 | 125x240 | 155x280 | 70x185 |

| 母模中心距離(mm) | 69 | 69 | 87 | 93 | 114 | 126 | 138 | 174 | 87 |

| 公模束(DXL mm) | 40x110 | 40x110 | 50x120 | 50x120 | 65x150 | 75x180 | 90x220 | 110x240 | 50x130 |

| 主滑板行程(mm) | 150 | 150 | 190 | 200 | 240 | 280 | 360 | 400 | 250 |

| 壓造力(ton) | 55 | 65 | 100 135 | 140 170 | 185 220 | 220 260 | 300 400 | 460 550 | 110 |

| 每分鐘最大產能 (pcs/minute) | 160 | 160 | 130 | 120 | 110 | 90 | 65 | 60 | 120 |

| 主馬達(hp) | 20 | 25 | 30 40 | 40 50 | 75 75 | 100 100 | 125 125 | 150 175 | 50 |

| 機械重量(ton) | 14 | 16 | 17 19 | 24027 | 38 43 | 60 65 | 77 85 | 115 128 | 26 |

質化.jpg)