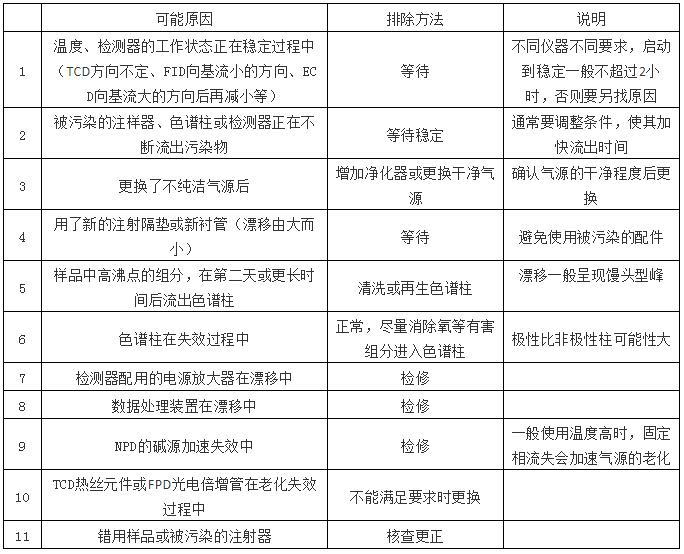

Description

C2500 Finished Product Inspection Machine-Single Station / Dual Station / Dual Station Barrel

Machine Features

- Working principle: the finished product inspection machine uses a servo motor to drive the driving pin wheel to row the material on the material reel on the working platform, use CCD CAMERA to obtain the image of the material, and send the image to the computer host. Apply the inhouse-developed software to perform OK and NG classification to achieve the purpose of visual inspection.

- Function: It can replace the shortcomings of traditional manual visual inspection. Not only is it fast, the standard is consistent, and it will not be missed.

- Excellent inspection and processing capabilities

- Independent development of light source, writing software, circuit design, free to set the test items, no need to repeat settings, parameters can be memorized

- Humanized and intuitive operation interface

- Independent color image processing

- The pre-rotation device, high-speed material supply, rotate the material belt to the condition of being put into detection.

- Paper tape / plastic tape can be shared

- High commonality: equipped with zoom lens, only need to adjust the magnification without changing the lens when changing the chip specifications.

- Manual visual confirmation

< Slide left and right to view product specifications >

Specifications

Sorting Items

Video

- Resolution: 1 ~ 50, μm / pixel (depending on camera resolution, lens magnification and chip size)

- CCD: Color High Speed CCD 640*480 pixels; CCD 1280*960 pixels;CCD 1920*1200 pixels

- Lighting: LED lighting (supplied with different light sources according to material)

- Power supply: 1PH 3? 220V 50 / 60 Hz

- Dimension: L55 X D110 X H196 cm (incl. warning light )

- Weight: 150 kg

- Inspectable Products: Various specifications of LEDs (TOP VIEW; SIDE VIER …); various specifications of semiconductor chips (QFN; ODFN; SMA; LTCC …); various passive components (resistance, exclusion, capacitance, displacement, inductance, discharge, Winding inductor)

- Applicable Size Range: 8mm~16mm

- Inspectable Items: Various dimensional checking, various broken corner checking, various text graphics detection; bubbles, copper leakage, debris, contamination, tin stain, electrode damage, wire tail too long, leakage welding, leakage line, multi-glue, lack of glue, even tin.

- Appearances: TOP view checking (single station); TOP, Bottom view checking (dual station)

?Speed: Paper tape 3000 pcs / min (depending on material size and testing items)

Plastic belt 1200pcs / min (depending on material size and testing items)