Description

Monitoring System

feature

- The monitoring system can input the information of our production equipment such as molding machine, screening machine, etc., or collect all kinds of data you need through the data collection box and put them into the database, which can display real-time information according to your needs; various reports (SPC, error and abnormality analysis…etc.) can be produced according to the customer’s needs.

< Slide left and right to view product specifications >

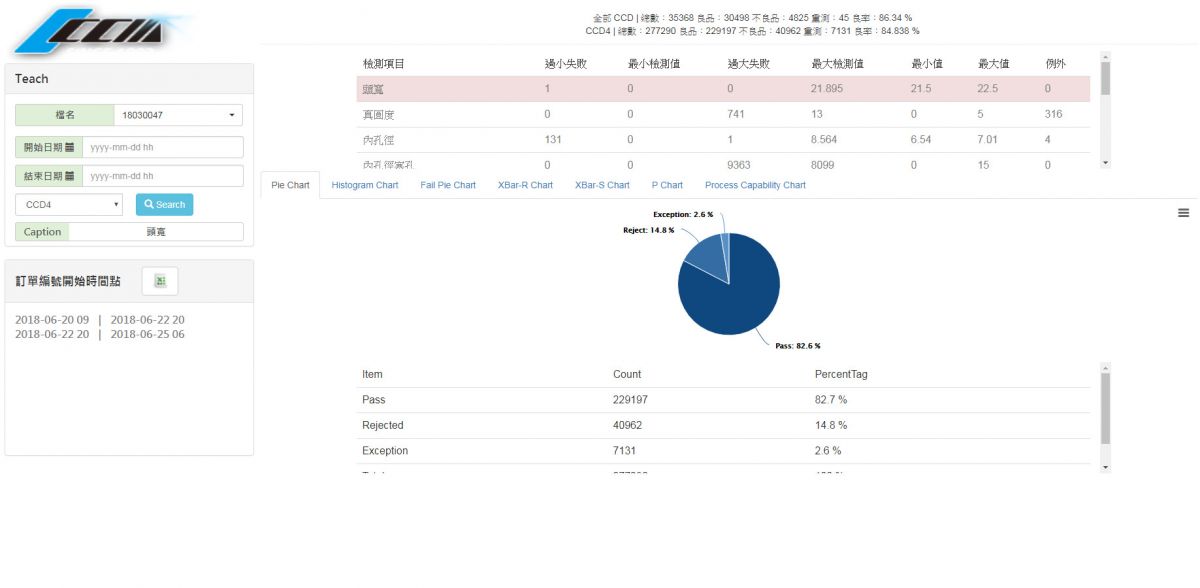

Real-time monitoring of sorting machines, molding machines, and process information monitoring boxes, and the monitoring system will read the database every 5~10 seconds. Take the sifter as an example, it can present its real-time “number of good products, number of defective products, yield rate, speed, specification, work order, etc.”. (Figure 1)

監(jiān)控.png)

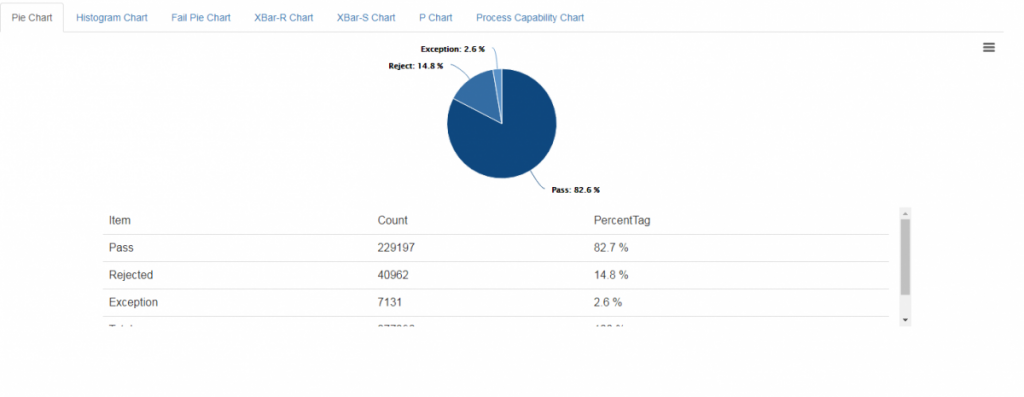

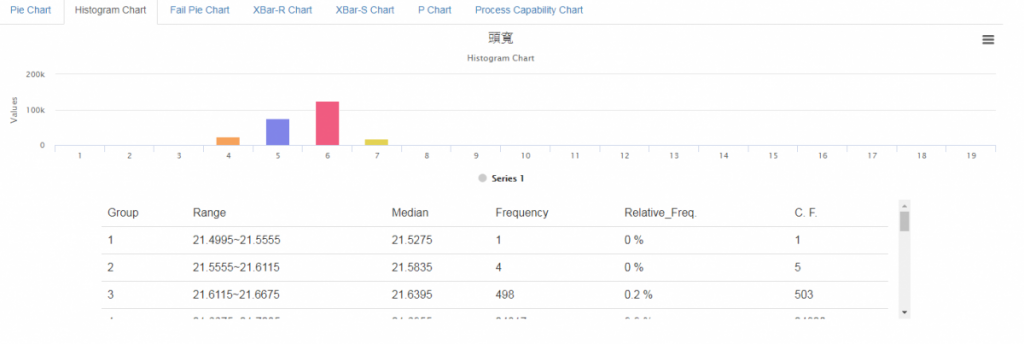

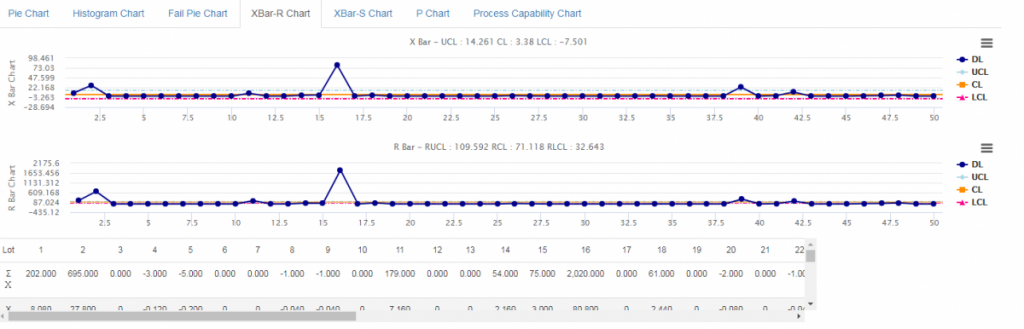

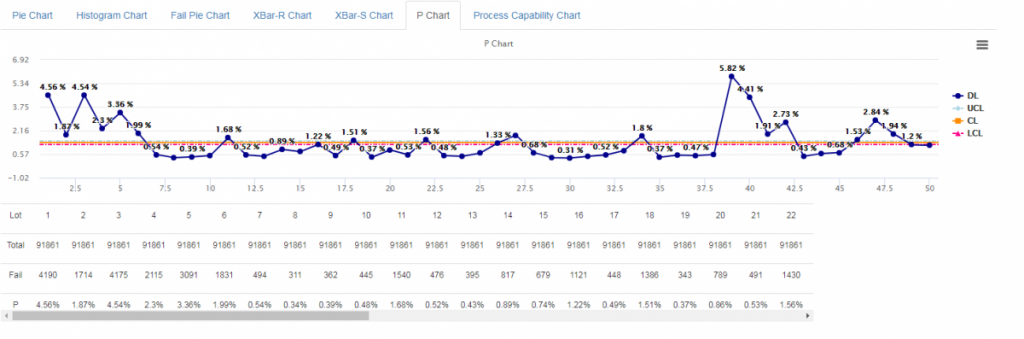

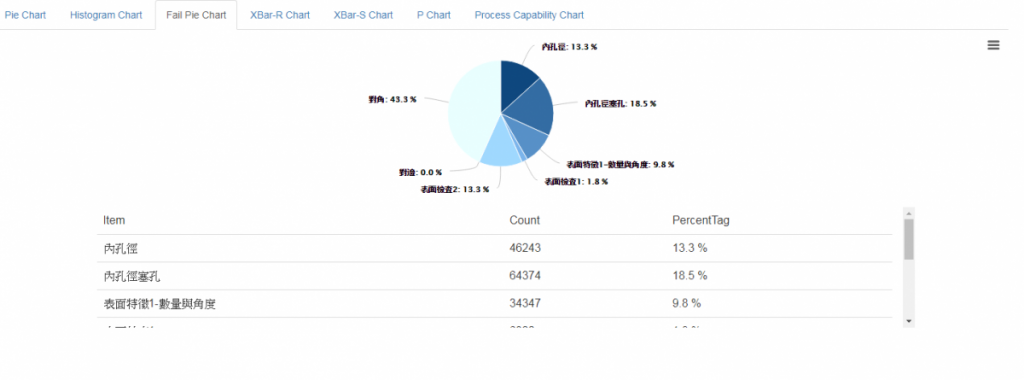

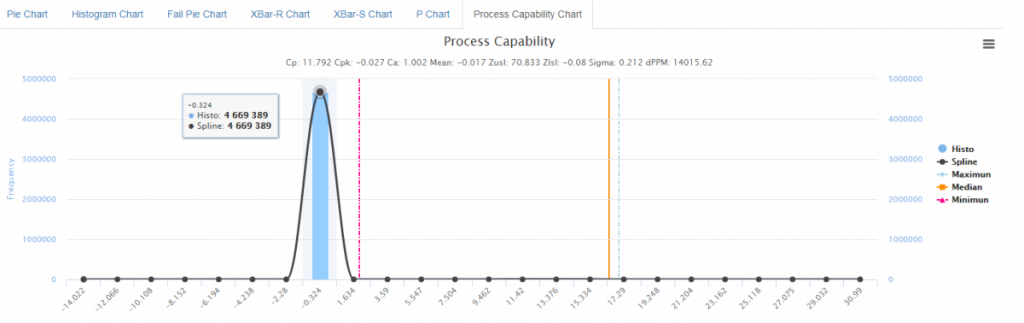

The monitoring system will integrate the data from the machines and export the reports (Excel), including production daily report (Figure 2) and SPC report (Figure 3). The daily production report can tell the daily “output value”, while the SPC report shows the production “quality” of each work order.

日?qǐng)?bào)表.png)

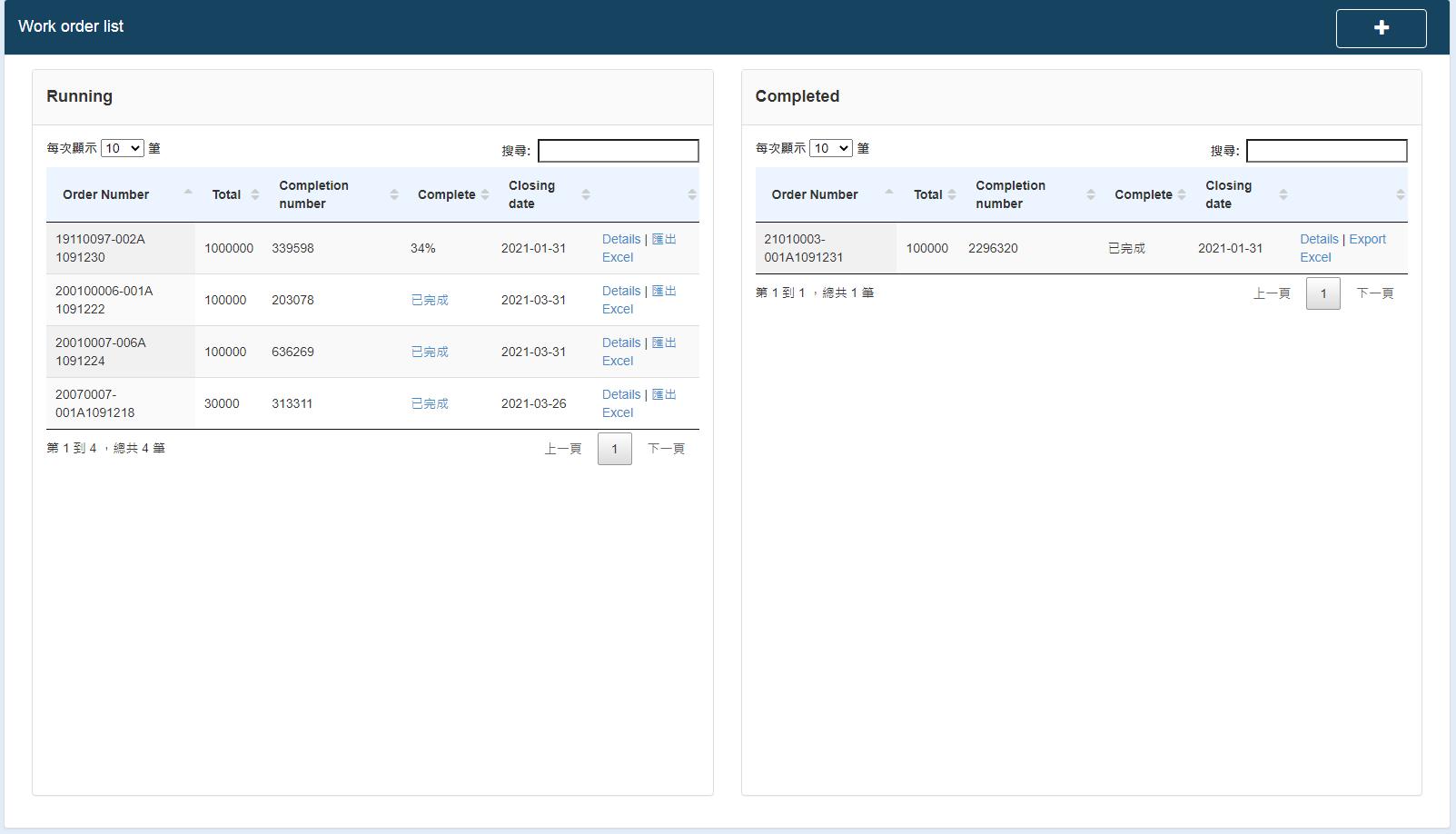

You can understand the status of work order execution. The work order list will present the information of all work orders, including the total number, completion degree, etc. After the work order is completed, the report can be exported in customized format according to the customer’s requirements. (Figure 4)

控.jpg)